Manufacturers of butterfly valves create these quarter-turn rotational motion valves, which are utilized in pipelines to stop fluid flow. People regularly highlight how butterfly valves can control flow. Manufacturers, however, do not advise doing this since it may harm the valve disk and negatively impact the sealing qualities. Read More…

Butterfly Valves & Controls, Inc. has been a premier supplier of quality butterfly control valves and other related industrial components for 25 years. We carry only the best parts sourced from world-class butterfly valve manufacturers. Extended service life and safe operation are at the core of every valve manufactured/assembled. Our catalog includes a large selection of valves, actuators,...

MDC Vacuum Products manufactures vacuum components. Our butterfly valves are low outgassing. The Del-Seal™ mini butterfly valves have a stainless steel internal surface, aluminum handle, metal seal or elastomer O-ring seal flange. Our Kwik-Flange butterfly valves are ISO KF flanges. Seal kits are available.

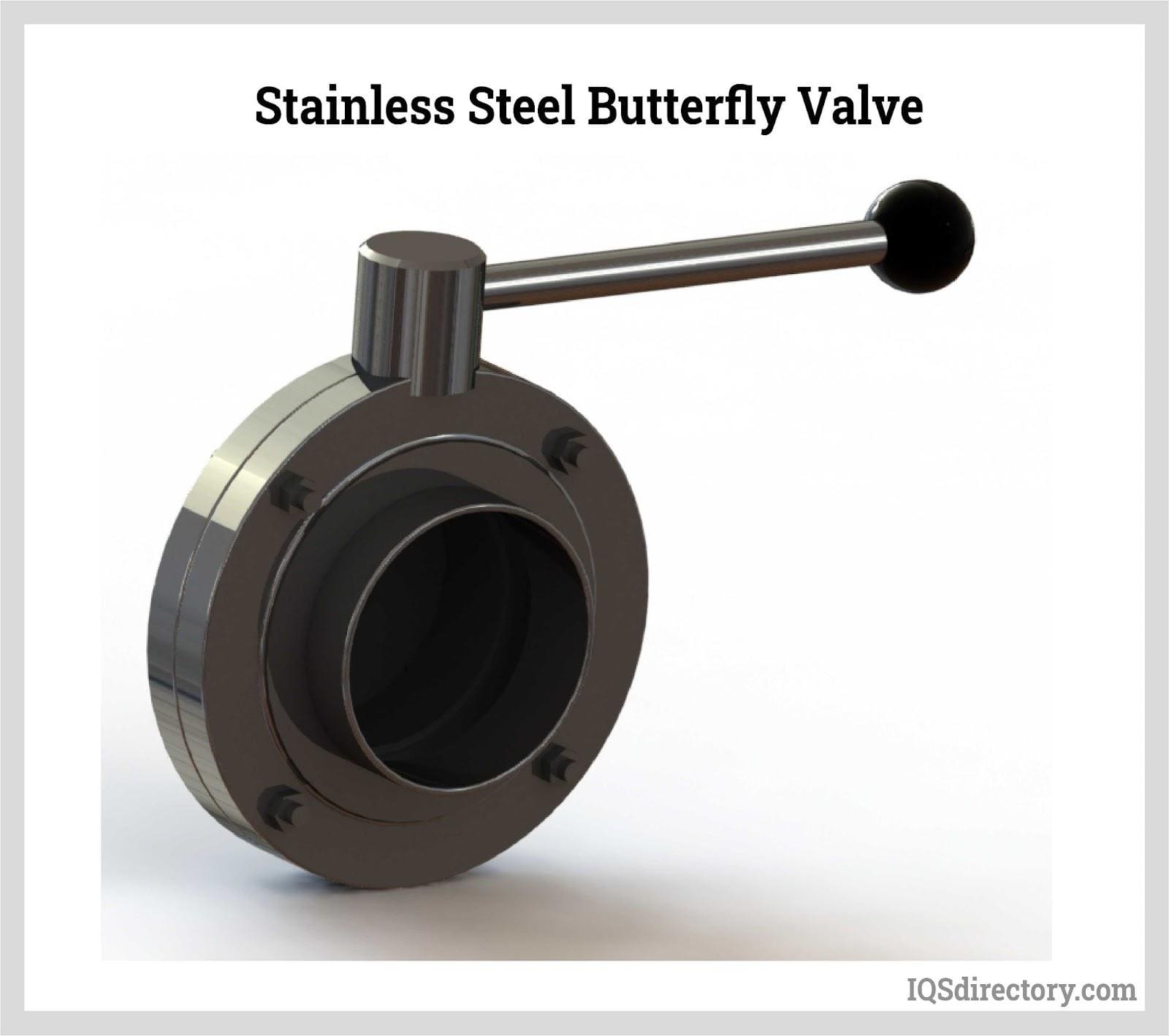

Nor-Cal Products is a leading distributor and manufacturer of isolation and throttling butterfly valves. Products and components are used for semiconductor, research and thin film deposition applications, as well as many others. We have earned worldwide recognition for our quality stainless steel butterfly valves.

DynaQuip Controls has been committed to producing excellent products for more than 40 years. We provide both automatic and manual ball valves. Some of our ball valve products include stainless steel ball valves, brass ball valves, high pressure, 2 and 3 way ball valves, screwed-body and mini valves.

More Butterfly Valve Manufacturers

They have a wide range of applications, particularly in flow isolation, and are utilized in a variety of process media and industries, including water distribution, collection, and supply, as well as pumping stations. They have several advantages over other valve families, two of which are their straightforward design and compactness. As a result, the finished products are lighter and less expensive, have smaller installation footprints, and have faster actuation rates.

Companies that produce butterfly valves also produce flanged double eccentric (double offset) type butterfly valves. This valve's double offset or eccentricity refers to the disk being offset twice from the valve body's center or the stem's axis of rotation.

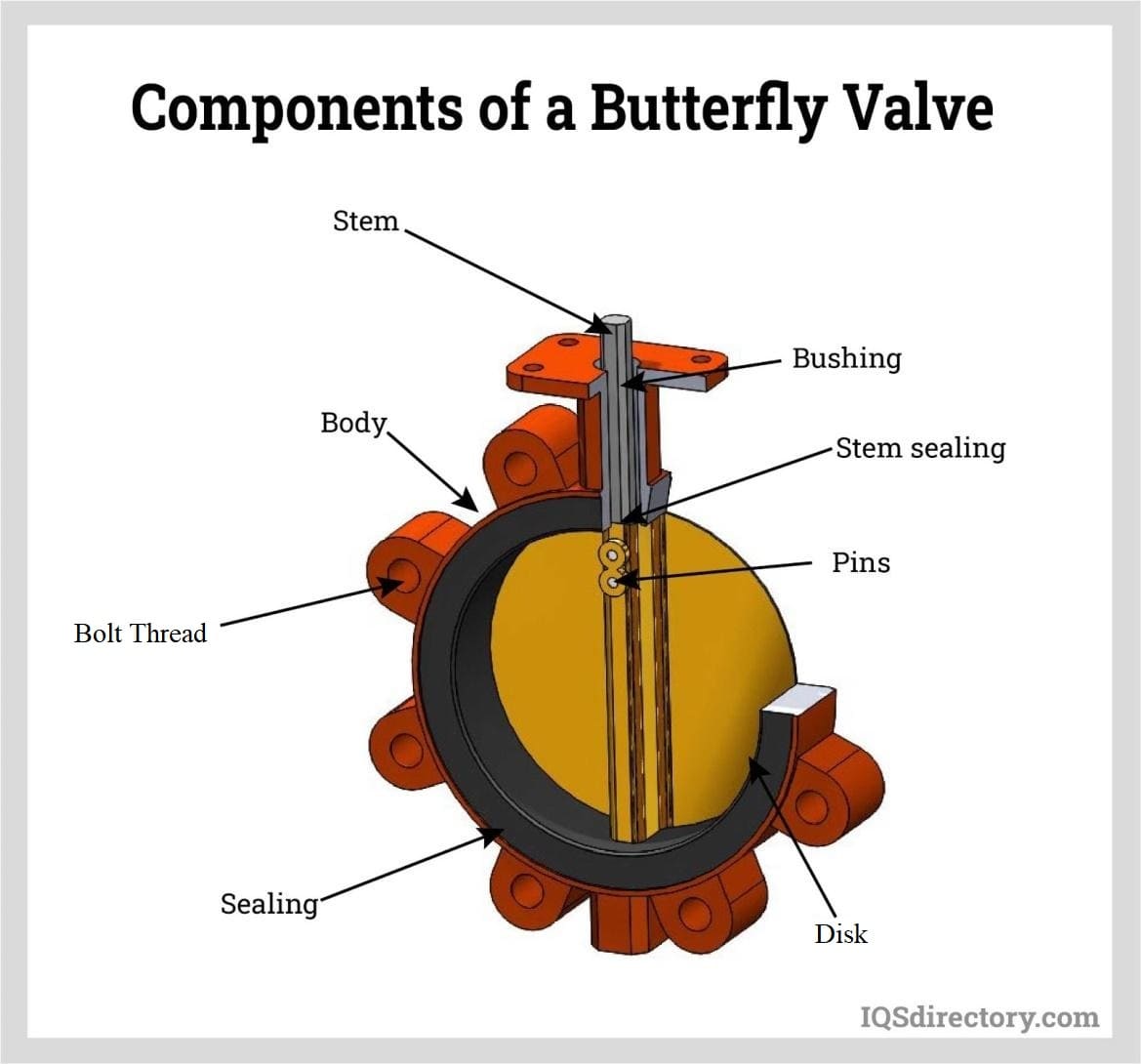

Major Butterfly Valve Components

Valve Body

The most typical end connection types for pipes are flanged, double lug, and wafer types, and the valve body fits in between them.

Disk

The disk, similar to a gate in a gate valve or a ball in a ball valve, is attached to the valve body and serves as a gate that restricts or stops the fluid flow. Normally, the disk is drilled to receive the stem or shaft. Depending on the butterfly valve manufacturer, there are numerous variants in disk design, orientation, and material to optimize flow, sealing, and operating torque. For instance, a double eccentric disk is intended to lessen operating torque requirements while reducing seal wear and "scuffing."

Seat

Strong elastomer or metal anti-leak seals hold the disk in a closed position to accomplish full shutdown along the interior valve body. Butterfly valve manufacturers utilize the stainless steel weld-filled and micro-polished integral body seat from the 9881k series to ensure a corrosion and erosion-resistant seat face. It is possible to construct the valve drop tight following EN12266-A specifications using this unique seat design.

Stem

The part that joins the disk to the actuation mechanism and transfers the torque through itself is the valve shaft, also frequently referred to as the stem.

Seals

At various valve interfaces, seals are present to either guarantee a tight seal during operation or to isolate the process medium from the internal components of the valve for a more adaptable and economical design.

A continuous T-profile robust sealing ring with a continuous T-profile ensures sealing on the seat face and is secured to the disk's edge by a retaining ring to prevent rolling out. The sealing ring is forced against the seat face in the closed position, creating a tight seal on both the upstream and downstream ends. Due to the double eccentric disk design, the sealing ring is fully undamaged in the open position.

The multiple O-ring shaft’s sealing technology offers maintenance-free sealing throughout the valve by preventing interaction between the process media and the stem/shaft. In addition, smaller, more specific parts are found in most other valve structures, such as bushings, bearings, and fasteners.

Butterfly Valve Working Principle

The fluid flow is managed by rotating the valve disk in a butterfly valve, which has a fairly simple design. The disk opens the valve bore when it is in the open position, aligned perpendicular to the flow direction to allow flow, and closes the valve bore when it is in the closed position. Butterfly valves often allow for bi-directional flow and cut-off. They are not full-bore, making them useless for swabbing or pigging.

Ductile iron is the body material, and both internal and external surfaces have an epoxy powder finish. According to the particular application requirement and technical standards, the valves are normally actuated by hand wheels, gears, actuators, or a combination of these.

Butterfly Valve Actuation

A butterfly valve can be operated various ways, including manually, semi-manually, or automatically. When creating butterfly valves, manufacturers take this into account. The makers of butterfly valves provide the following actuation techniques.

- Electric: Uses an electric actuator to operate the valve using a 4-20 mA control signal and is frequently used for time-critical applications that require high precision regulation.

- Pneumatic: Utilizes pressurized air for actuation and is also employed for high-precision applications.

- Hydraulic: Typically employed when opening and closing the valve requires enormous torques, such as high pressure and high viscosity applications.

- Manual: Manually-operated butterfly valves are turned by a hand wheel, crank, or lever. Levers are frequently attached to smaller manual valves. Hand wheels and a gearbox are offered to transfer the torque with a high mechanical advantage for larger sizes. Another method of manual actuation involves using an extension spindle, adapter, or square cap, and the appropriate T-key from the ground level when the valve is buried underground without a manhole.

Butterfly valves are less expensive to size and install than other valve types, such as gate valves, because they require less torque by nature.

Advantages of Butterfly Valves

Butterfly valves, in particular for dimensions over DN 200 (200 mm) in size, can provide important advantages over other types of valves depending on the application.

- Lightweight and Compact: Butterfly valves have a much smaller installation footprint due to their compact design and smaller face-to-face size. They also cost less to install due to lower labor, equipment, and piping support expenses.

- Low Maintenance Requirements: Their need for maintenance is drastically reduced by an economically-sound design with fewer moving parts and hence fewer wear points.

Choosing the Proper Butterfly Valve Manufacturers

To make sure you have the most productive outcome when purchasing Butterfly Valves from a Butterfly Valve Manufacturer, it is important to compare at least 6 Manufacturers using our Butterfly Valve Manufacturers directory. Each Butterfly Valve Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Butterfly Valve Manufacturing business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Butterfly Valve Manufacturing companies with the same message.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services